Oil Press,Small Oil Press,Screw Oil Press,Oil Presses China.

Oil Seed Press,Oil Press Machine,Oil Mill, Groundnuts Oil Press.

Oil Press

Henan Double Elephants machinery Co., Ltdsupplies various oil press to different clients' needs

Home->>Product>>Screw Expeller Press

Working Theory of Screw Expeller Pressing

Screw expeller pressing is to separate the oil from oil bearing materials by the pressing power which comes from the change of chamber volume, drive from screw worm, resistance of curve teeth at press rings and extrusion friction between oil materials. Under the big pressure created in press chamber, the oil can be discharged from gap of press bars and oil trough of press rings. Either big scale and small scale of screw oil expeller, they have similar theories in screw expeller pressing. Because the screw type seed oil expeller is mainly used by extrusion theory, so it is also called as oil extruder or oil extrusion process..

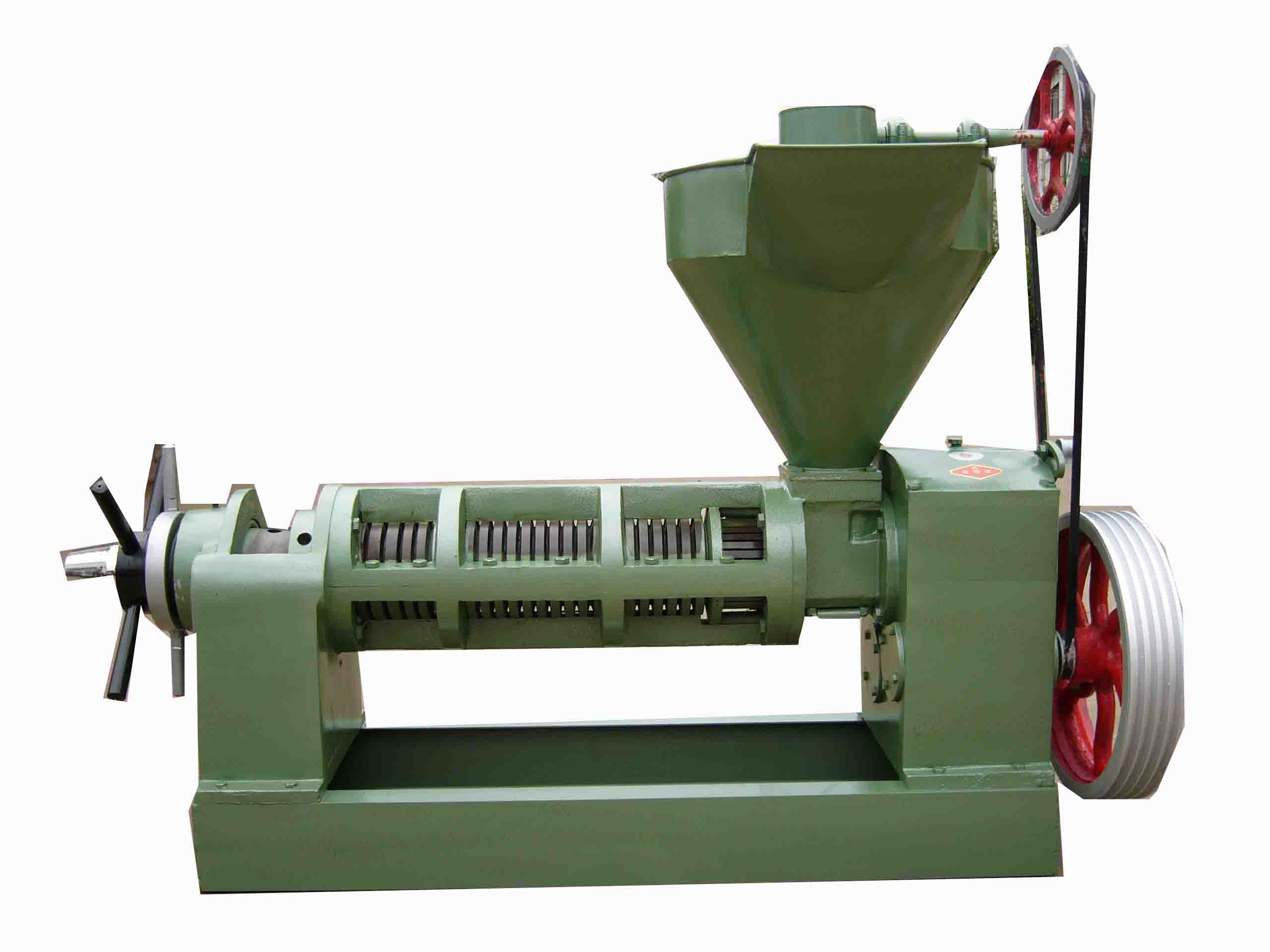

The structure of Screw Oil Press

Screw oil press are mainly composed by shift gears box, press cage, feeder, press screw, and machine frame. The five parts are the main structure of screw oil press. The screw type seed oil expller is an crude oil processing equipment.

The Process of Screw Expeller Pressing

By using the pressure of dynamic extrusion to extract the oil from material, the material is pushed forward in the press chamber. Except of feeding hopper, the press chamber of the main working parts of screw oil expeller, which is composed of a worm shaft and round bar cage. There are two type single stage press and double stage press. There is only one horizontal chamber in single stage press. Double stage press is to add a straight chamber to single press for first class press.

Worm shaft is a shaft with worms and collars. Every worm have thread pitch and thread depth. With the thread pitch of the worm shaft becoming shorter and thread depth becoming shallow, the volume of press chamber is reducing from feeding hopper and discharging port. Material is pushing out along the worms. The oil can be extruded out gradually with the increasing pressure from press chamber. There are gaskets between round cage bars, which form gaps where the oil flow out.

Compared to small oil press, big scale seed oil press always equipped with scraper in chamber. The edge of scraper comes deep into the chamber and aims at every collars to prevent materials from skidding run in the chamber and return. The scraper can also adjust the thickness of cakes and control the pressure of chamber to reduce oil residue ratio. The big scale screw oil press also have cake binder to make the surface of residue cakes smooth and clean. Cooker is usually combined together with oil press to make cooking and pressing continuously processing.

The prepress expeller is to prepress oil materials by bigger pressure. The crude cakes are fed into screw oil expeller to press or extracted oil by solvent. So its structure is a little different from common seed oil expeller. The volume of chamber in feeding parts and discharging parts change greater. The capacity of prepress expeller is bigger, too.

The screw oil press can work continuously, so it need little labor. The residue cake after oil extraction is small and thin. The screw type seed oil press is popular and easy in application. But the main parts in chamber is easy to wear, which need change at a certain time, so the spare parts increase the working cost at a certain extent.

The screw type seed oil presses are very popular in the process of granule oilseeds such as rape seeds, peanuts, soybean (Soya), sesame seeds, cotton seeds, sunflower seeds, Jatropha curcas seeds, Oil-tea Camellia Seed, canola, coconut, palm oil, palm kernel etc.

More about Screw Oil Press...» Big Scale Oil Press » Canola Oil Press» Palm Oil Press »

Images of Screw Oil Press

|

|

|

| YZS-68 Oil Press | YZS-80 Oil Press | YZS-95 Oil Press |

|

|

|

| YZS-100 Oil Press | YZS-120 Oil Press | YZS-130 Oil Press |

- Oil Press of Small Scale

- Oil Press with Electrical Heater

- Oil Press with Diesel Engine

- Autamatic Oil Press

- Filter Press

Working Theory of Screw Expeller Pressing

Screw expeller pressing is to separate the oil from oil bearing materials by the pressing power which comes from the change of chamber volume, drive from screw worm, resistance of curve teeth at press rings and extrusion friction between oil materials. Under the big pressure created in press chamber, the oil can be discharged from gap of press bars and oil trough of press rings. Either big scale and small scale of screw oil expeller, they have similar theories in screw expeller pressing. Because the screw type seed oil expeller is mainly used by extrusion theory, so it is also called as oil extruder or oil extrusion process..

Link:Small Oil Press Oil Presses

E-mail:dbph@oilpressmachine.com

© 1992-2009 Henan Double Elephants machinery Co., Ltd. All Rights Reserved.